Mechanical Testing

Agro Met Lab

Mechanical Testing

Physical properties of a metal is based on its composition and its structure influences the behavior of the metal under various conditions. Tensile, hardness, bend and impact testing ensures the strength and durability of the metal. These tests are conducted to meet the requirements set forth by International standards. Agro Met Lab is well equipped with knowledgeable technicians and engineers to perform most standard mechanical testing as per ASTM, BS, IS, ISO, AWS, ASME or client specified standards.

Agro Met Lab

Mechanical Analysis

- UTM of 400 KN capacity SERVO Controlled

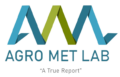

- Tensile Testing (UTS, YS, 0.2% PS, % Elongation and % RA)

- Bend Test (Face, root,side, rebend)

- Compression

- Flaring / Flattening

- Shear test

- Proof Load (Fasteners also)

- Load test on Products, Components, Screw Jack, Wire Rope, etc.,

- Load Vs Deflection characteristics and Endurance test on Compression & Extension Springs.

- Building Materials as Bricks, Concrete Cube, or Steel Rod, TMT Bar, etc.,

- Customised load tests (pull out loads, push out load, breaking load, etc.,

- Welder qualification tests as per ASME Sec IX, IS,BS, ISO standards

Mechanical Analysis

HARDNESS

- Rockwell hardness Test (HRA, HRB, HRC)

- Brinell hardness Test (Up to 3000 kgf)

- Micro Vickers Hardness Test (10gm to 1000gm)

Mechanical Analysis

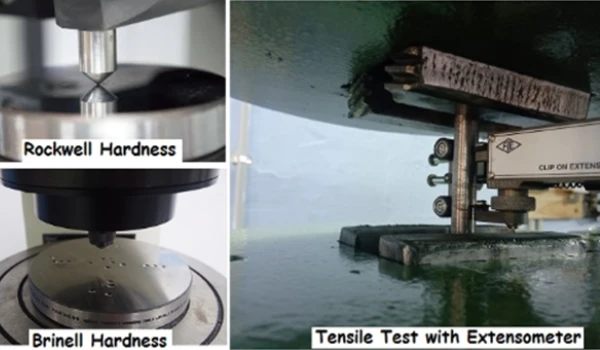

IMPACT TEST

AML have Complete workshop facilities including Lathe Machines, Shaping Machine ,Surface Grinding Machines ,Milling Machines and Drilling Machines.

Complete Set of Measuring and inspection instruments including Vernier Calipers, Micrometers, and Dial Gauges.Number of fixtures and attachments for various tests.

- Charpy / Izod Impact Tester

- Charpy test till -196 C

- Both U and V notch

Mechanical Analysis

Facilities we have for Mechanical Testing

Rockwell Hardness

Vickers hardness tester

UTM

Brinell Hardness Testing Machine